How to choose the best rope for mooring operation

Choosing the best rope for mooring operations involves considering several key factors to ensure safety, efficiency, and longevity. Here's a comprehensive guide to help you select the most suitable mooring rope:

Material:

dyneema (UHMPE): Known for its high strength-to-weight ratio, low stretch, and durability. Ideal for fast and efficient operations.

Polyester: Offers good strength, UV resistance, and low stretch. A balanced choice for general mooring.

Nylon: High strength and excellent elasticity, which can absorb shock loads. Suitable for dynamic mooring conditions but stretches significantly.

Polypropylene: Lightweight and floats on water. However, it has lower strength and abrasion resistance compared to other materials.

Strength:

Ensure the rope's breaking strength exceeds the maximum expected load. Consider factors like the size and weight of the vessel, as well as environmental conditions.

Stretch and Elasticity:

Low stretch ropes (like dyneema) provide better control and reduce the risk of snapping back under load.

High elasticity ropes (like Nylon) can absorb shock loads but may require more adjustment during mooring.

Durability and Resistance:

Look for ropes with high abrasion resistance, UV resistance, and resistance to chemicals and saltwater. These properties ensure longer life and reliable performance.

Handling and Flexibility:

Choose ropes that are easy to handle, flexible, and can be easily spliced. This makes mooring operations more efficient and less labor-intensive.

Diameter and Length:

Select an appropriate diameter that provides the necessary strength without being too bulky to handle.

Ensure the rope length is sufficient for the mooring configuration and the specific needs of the vessel and port.

Buoyancy:

ropes that float, like those made of dyneema or polypropylene, can simplify operations over water, making them easier to see and retrieve.

Cost:

Balance the initial cost with the expected lifespan and performance of the rope. While higher-quality ropes may be more expensive, their durability and efficiency can offer long-term savings.

Compliance with Standards:

Ensure the rope meets relevant maritime standards and regulations for mooring operations. This ensures safety and reliability.

Manufacturer Reputation and Reviews:

Consider ropes from reputable manufacturers known for quality and reliability. Reviews and recommendations from other users in similar applications can also be valuable.

Example Recommendations:

For large commercial vessels requiring high strength and minimal stretch: dyneema (UHMPE) ropes are an excellent choice.

For general-purpose mooring where balanced performance is needed: Polyester ropes are a reliable option.

For situations where shock absorption is critical: Nylon ropes offer the necessary elasticity and strength.

By carefully evaluating these factors, you can select the best mooring rope that meets your operational needs and ensures safe and efficient mooring operations.

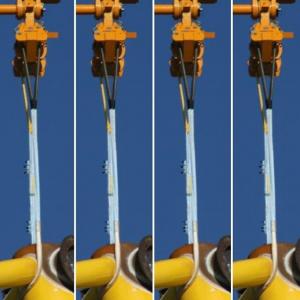

dyneema rope can facilitate faster mooring operations due to several of its advantageous properties:

1. Lightweight: dyneema is significantly lighter than traditional materials like steel wire or polyester rope. This makes it easier and quicker to handle, reducing the physical effort required by crew members during mooring.

2. High Strength-to-Weight Ratio: Despite being lightweight, dyneema has a very high strength-to-weight ratio. This means that ropes made from dyneema can handle high loads without being as cumbersome as heavier ropes, streamlining the mooring process.

3. Low Stretch: dyneema ropes exhibit minimal stretch under load, providing more immediate and precise control over the vessel during mooring. This reduces the time spent adjusting and readjusting the lines to achieve the correct tension and positioning.

4. Flexibility and Handling: dyneema ropes remain flexible and manageable even after repeated use and exposure to the elements. Their flexibility allows for easier and quicker deployment and retrieval compared to stiffer traditional ropes.

5. Durability: Dyneema is resistant to abrasion, UV light, and chemicals, which means the ropes maintain their performance characteristics over a longer period. This reliability reduces the downtime for inspections and replacements, contributing to overall faster operations.

6. Buoyancy: Dyneema ropes are buoyant, which simplifies operations over water, making it easier to see and retrieve the lines, thus speeding up the process.

These properties collectively contribute to more efficient and quicker mooring operations when using Dyneema ropes compared to traditional rope materials.