What should be considered when want to buy the ropes

What should be considered when want to buy the ropes

1. Kind of ropes ( material composition)

Nylon, Polypropylene, Polypropylene twine, Polyethylene, Vinylon, Polyester, Nylon filament, macromold polyethylene, aramid and mooring rope combination etc.

Polypropylene rope, polypropylene filament composite (line) rope and macromolecule rope can floating on the water for its water non-absorbent.

Polyamide (nylon) cable will be submerged in the water because of water absorbent.

Polyester rope will sink in water because of its linear density.

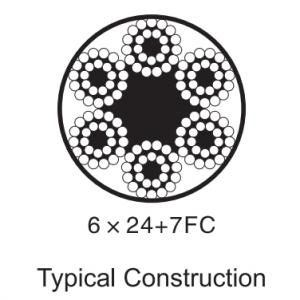

2. Constructions

3-strand, 4-strand, 6-strand, 8-strand, 12-strand, 16-strand and multi-strand rope etc

3.Diameter, length and breaking strength

Normal length is 220 meters per coil by users, breaking strength is only a reference value, based on new and unused rope test.

4.In order to reduce cable damage, please pay attention to whether need protect jacket.

Usage of different fiber ropes

1.Polypropylene (PP) rope

Ropes made of polypropylene fiber whose linear density is less than 1, with soft, abrasion resistance can floast on the water ans has a close strength and elongation when wet and dry.

This kind of rope can be widely used in transportation, oil fields and mines etc.

2.Polyamide (Nylon) rope

Using polyamide monofilament or cord whose linear density is greater than 1 as raw materials, the ropes has good performance such as high strength, good impact resistance, wear resistance, corrosion resistance etc.

The products are widely used in the large vessels, warships, tugs, oil fields, mines and other areas.

3.Polyester (PET) rope

Raw material of this rope is polyester fiber, its linear density is greater than 1. with soft, good abrasion resistance, anti-aging, UV resistance and corrosion resistance, the ropes can be widely used in marine transportation, oil tankers and port etc.

4.Mixed polyester and polypropylene (PET/PP) rope

The rope's raw material is polypropylene and polyester whose linear density is less than 1. The melting point of rope is 260℃ /165℃, the ropes are soft, abrasion resistance and floating on the water, anti-aging, anti-UV, anti-corrosion.

The products are widely used in shipping vessels, oil tankers, haulage and other areas of the port.

5.Macromolecule polyethylene (HMPE) rope

This fabric is about 87.5% lighter than the same diameter of wire rope, can float on the water. it is the strongest in the world, 1.5times stronger than the same diameter of wire rope. Excellent corrosion resistance, antifatigue, abrasion resistance, UV resistance and electric insulation. It is widely used in shipbuilding, national defense, port haulage and offshore industry.